As a truck driver, it’s unavoidable not to be in situations where you’d need to jack up your semi-truck.

Jacking up and doing some checking could save you from a lot of daily difficulties. Changing oil, troubleshooting, and inspections are some of the things that can be done by jacking up the truck.

A study showed that the greatest danger when dealing with a forklift happens when the forklift tips over.

However, we have prepared curated steps to make lifting up a semi-truck easy for you.

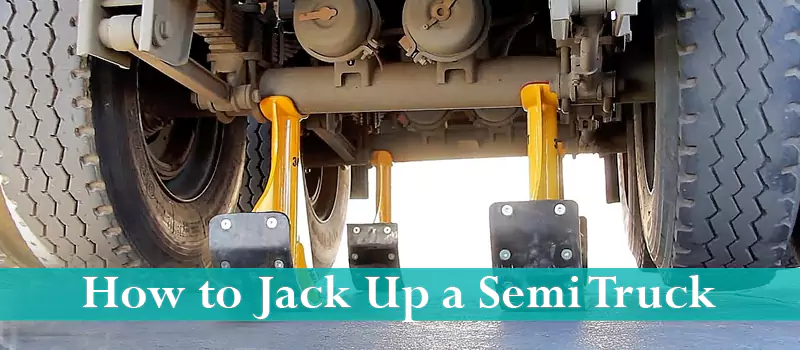

Process of Jacking Up a Semi Truck

Tools Required

To lift up a semi-truck, you will need some necessary tools. These tools are the prerequisites to a smooth truck-lifting.

Jack

A jack is a mechanical device that is used in raising vehicles. There are many types of jack like scissor jack, floor jack, bottle jack.

The most used jacks for jacking up a semi-wheel are hydraulic jacks and air-over-hydraulic jacks. Hydraulic jacks are widely used due to their ability to lift heavy loads.

Hydraulic jacks have cylinders that can hold hydraulic fluid and a pumping system that moves the fluid through the cylinder.

When mechanically activated, this process leads to the exertion of pressure that lifts a vehicle.

The air-over-hydraulic jack is activated by compressed air instead of a mechanical movement of the pump lever.

Jack Stand

A jack stand is a necessary tool to have when trying to jack up a semi-truck. You should never get under any vehicle without a jack stand.

Step 1: Park in a Quiet and Safe Spot

Park in a quiet, less busy spot, safe spot. You’ll need calmness when jacking up to fix a problem.

In fact, you can place a tag that notifies other vehicles that your big truck is being serviced.

Step 2: Park on a Hard and Even Surface

A hard and even surface is your best bet when trying to park a semi-truck. A soft surface may not be able to withstand the pressure of the semi-truck, especially with a load.

Regardless of how urgent the situation is, you should always find the ideal surface. Nothing is more urgent than staying alive

Step 3: Block the Wheels With Chocks

Chocks are wooden materials used as a filler to stop the wheels from moving. Before you get a bit technical, you should check the idle tires.

If the truck moves while on a jack stand, this could lead to a fatal accident. You should always have chocks in your semi-truck.

However, you can opt for other effective tools like bricks and wooden boards if you don’t have chocks.

Step 4: Apply a Brake

No one will forget to apply a brake before jacking up and creeping under a big truck. But in case it didn’t occur to you, you should apply a brake before taking another step.

Step 5: Grab Your Hydraulic Jack

At this point, you can bring out your hydraulic jack. Don’t use the emergency jack for routine repairs.

You should have a hydraulic jack with you every time.

Emergency jacks aren’t durable and may not withstand pressure for long minutes because they are mechanical. Use a hydraulic jack or an air-over-hydraulic jack.

Step 6: Locate a Secure Jack Point

Your hydraulic jack should be in perfect shape. Once you notice any sign of disrepair, you should prioritize replacing or repairing your jack.

After ensuring that, you need to find the jack point for your truck. A jack point is an area designated to connect with a jack.

It is important to place the jack under the right spot. Check the owner’s manual to know the jack spot.

What should you do in situations where there isn’t a manual or a recommendation? Place the jack under the axle. The jack’s saddle should be centered directly under the saddle.

Step 7: Lift the Semi Truck

You can place a jack in the middle of the axle to raise both ends if the semi is not fully loaded. However, if you’re raising one end at a time, place the jack at that side.

After making sure the jack is properly placed under the axle, pump the lever. Pump until it lifts up the axle to a proper level.

Step 8: Place Jack Stands at Both Ends of the Axle

Use jack stands to hold the semi at both ends of the axle. Like in the case of jack, center the saddle under the axle.

Then slightly lower the axle with your jack until the stands are holding the semi.

Step 9: Remove the Jack Stands After Servicing

What should you do when you’re done with servicing? Raise the axle with your jack and remove the jack stands. Opposite of what you did in the previous step.

Step 10: Lower the Semi Truck and Remove the Jack

Lower the axle by operating your jack until the semi is back on the floor. Then remove the jack.

Related Guides:

Reasons Why You Should Use Jack Stands

1. Pressure

Jacks are not designed to withstand pressure – that is the work of a jack stand. Even user guides for some jacks will advise you against doing this.

There are many things that could go wrong with using a hydraulic jack as a stand.

2. Inherent Safeness

Jack stands are designed in a way that it is easy to figure out problems. You can see a potential failure by carefully observing a jack stand.

3. Complexity

Hydraulic jacks are sophisticated. It is difficult to figure out potential failures as you can easily do with jack stands.

4. Lack of Balance

leaving a commercial truck on a hydraulic jack for long may create a misbalance. Both sides may not be equally jacked up.

5. Risk

Using a hydraulic jack as a stand is just straight-up risky. Many people have been crushed as a result of this.

Conclusion

You can raise a semi-truck anywhere on the axle. Just make sure you have your jack and jack stands in perfect shape. Using a jack and enough jack stands is key to successful truck-lifting.

You will be raising a semi-truck countless times since it is now fun and easy. Knowing this, you need to always check up on your jacks and stands before driving.

Take proper care of your jacks and stands by oiling them and storing them appropriately. You can follow the manufacturer’s instructions in maintaining your jack and jack stands.