Choosing a suitable type of hydraulic press is very important when considering your garage space or load of work.

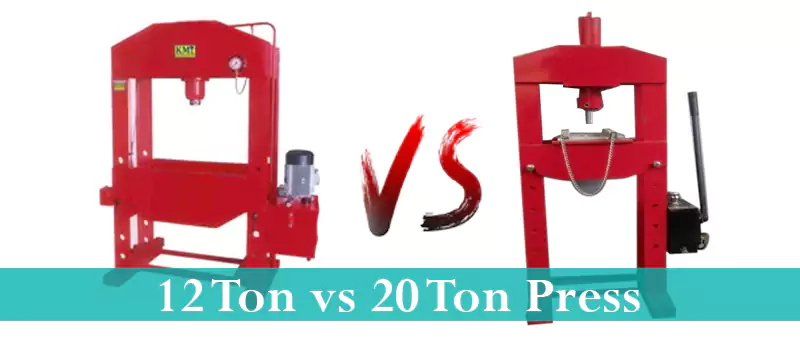

Hydraulic press varies from type and amount of work that each one can process at different times and also the garage space. So, 12 ton vs 20 ton- Which hydraulic press option will be better?

The 12-ton press is a hydraulic press machine that creates massive pressure for the press out and arbor jobs. It is great for stamping, straightening, pressing, bending, and doing bearing work for any metalworking job.

The 20-ton press also known as the pneumatic press uses air pressure or a pump handle to activate the hydraulic ram.

It removes pressed-in objects, crushes things, and provides up to 20 tons of force to operate simple tools.

What is 12 Ton Press?

The 12-ton hydraulic press is a machine press using a hydraulic cylinder to generate a compressive force. It uses the hydraulic equivalent of a mechanical lever.

The 12-ton press is great for stamping, straightening, pressing, bending, and doing bearing work for any metalworking job.

The 12-ton press has a heavy-duty H frame steel construction, an easy pumping system that has a long handle, slide-over tables that fit between the sides, a 21-inch working range, single-acting spring return hydraulic ram that works perfectly for speedy work.

It also has an adjustable lower bolster platform.

What is 20 Ton press?

The 20-ton hydraulic press also known as the pneumatic press uses air pressure or a pump handle to activate the hydraulic ram.

The air adds speed and the pump handle adds precision to the job.

The pump comes prefilled with hydraulic oil and needs to be primed before it is used.

The upper oil feed hose includes a check valve. If the fitting is not tightened the ram will not retract when the pressure valve is opened.

12 Ton vs. 20 Ton press

Difference 1: Weight

The 20-ton press as compared to the 12-ton hydraulic press is much bigger and works effectively.

Though it might be much bigger for your garage space, most people still consider the 20 ton when going to purchase a hydraulic press.

The 12 ton on the other hand is much smaller. Though the difference in weight between the two is only 8 tones.

Difference 2: Cost

The 20-ton press is typically more expensive than the 12-ton hydraulic press. However, the material used to make it provides good value for money because of its durability and functionality.

Difference 3: Maintenance

The 12-ton press requires minimal maintenance and care over time, while the 20-ton hydraulic press requires more care and maintenance.

This makes the 20-ton press costly too. The 20-ton press needs to be regularly maintained to avoid faults during work.

Both hydraulic presses need to be maintained but the 20-ton hydraulic press needs maintenance most.

Difference 4: Capacity

The 20-ton press has more capacity as compared to the 12-ton press. With the 20-ton press, you can be able to use the press brake kit.

The 20 ton fits well on the narrow gap the press plate rests on. The 12 ton on the other hand has lesser capacity.

Difference 5: Space

When considering space at your garage you can choose the 12-ton press. The 20-ton press is bigger and eats up too much space.

So, when considering a hydraulic press that will suitably fit your garage then you should go for the 12-ton hydraulic press.

Difference 6: Appearance

Considering purchasing a hydraulic press, one must be able to identify what they want when they get into the shop. Therefore, you should be able to identify or describe the appearance of the hydraulic press you are in need of.

The 12-ton press has polished inner cylinder walls which extend the life of the hydraulic seals.

The 20-ton hydraulic press on the other hand has an all-welded steel construction. These characteristics make them differ in appearance.

Difference 7: Availability

When it comes to availability, the 12-ton hydraulic press is readily available in shops.

The 20-ton hydraulic press on the other hand is most often scarce and not available in most shops not unless it is being shipped from abroad or from where the hydraulic press is being manufactured.

Related Helpful Guides:

The Pros and Cons of 12 Ton Hydraulic Press

Pros

- It is space-conscious

- The 12-ton press is easy to maintain

- It is easily available in shops

- It is less costly

- The 12-ton press is much lighter as compared to the 20-ton press

Cons

- The 12-ton press is not durable

- It has less capacity as compared to the 20-ton press

Pros and Cons of 20 Ton Press

Pros

- The 20-ton press is durable as compared to the 12-ton hydraulic press

- The 20-ton press has extra capacity

- The 20-ton press can be handled with minimum effort

Cons

- The 20-ton press is quite expensive

- The 20-ton press is not easily available

- It is space-consuming as compared to the 12 ton

Conclusion

After looking at the 12-ton press and the 20-ton hydraulic press, I hope you are able to decide which hydraulic press type is best for your garage and working space.

It all boils down to personal preference and tastes, but most people will tell you that the 20-ton press is much better than the 12-ton hydraulic press.

Though each hydraulic press works best for everyone’s own interests.

There’s also no need to limit oneself to one type of hydraulic press. Each hydraulic press just works perfectly.